Overview

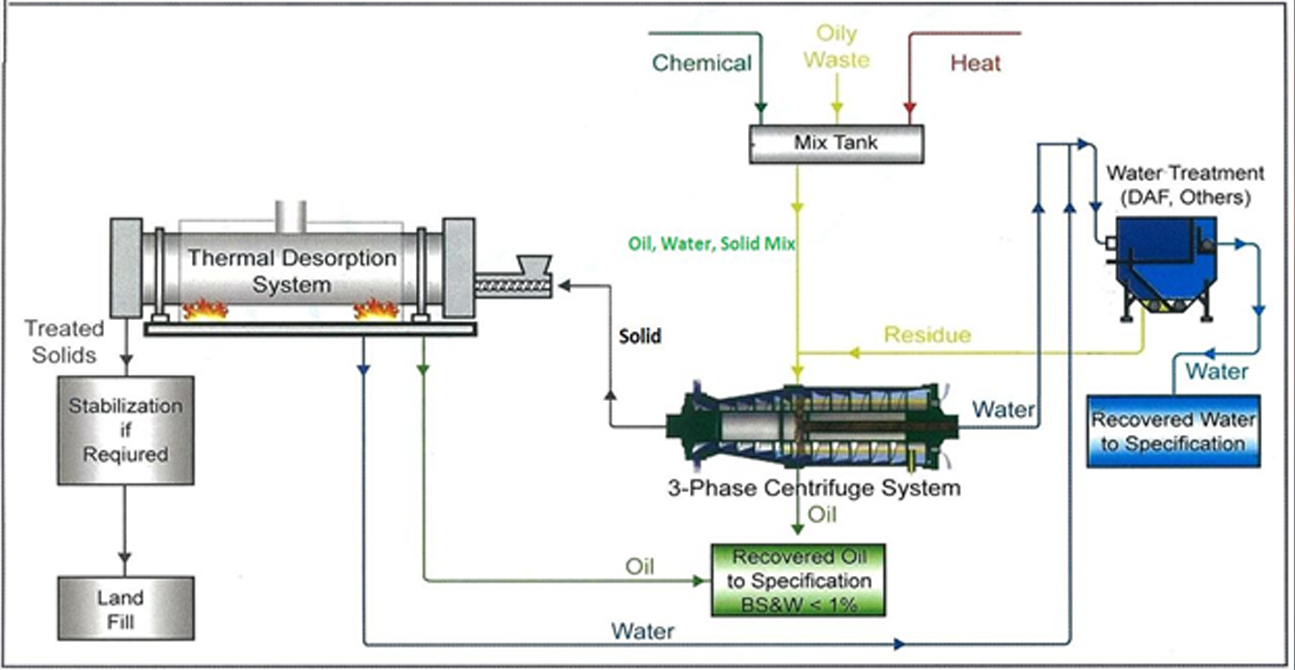

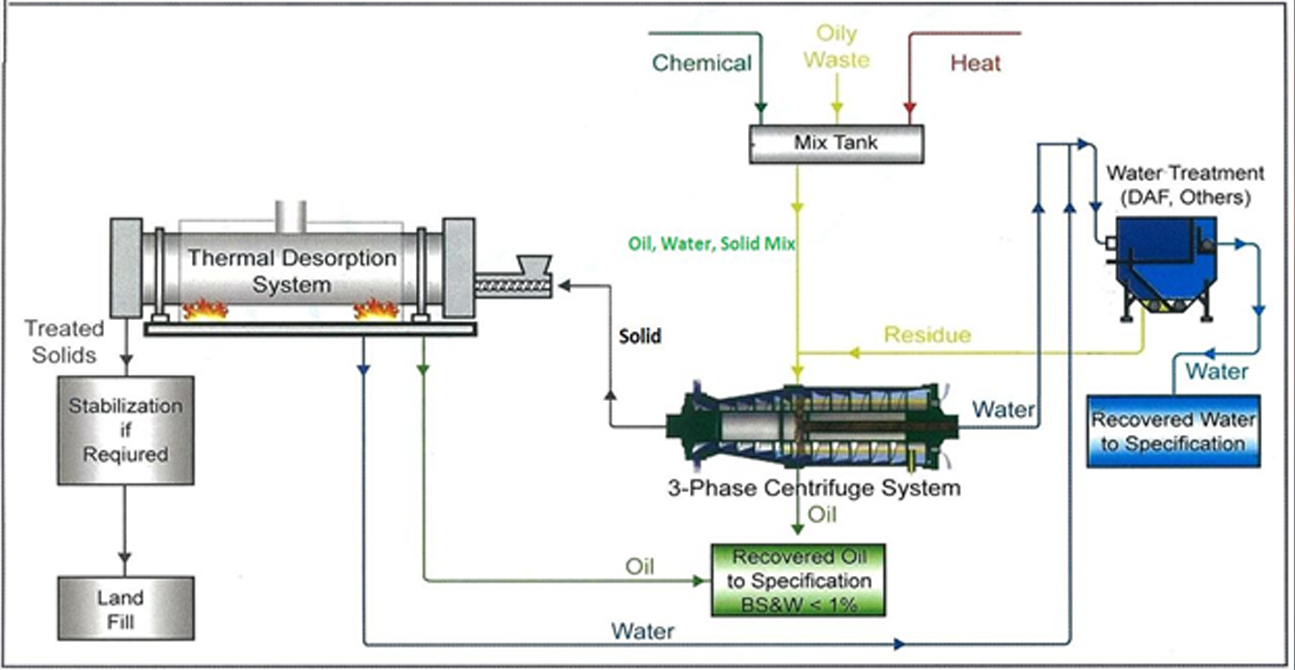

SMIW Co operates a 100% hydrocarbon recovery system to handle the following types of oil wastes, e.g. Slop Oil, API Separator Sludge, Tank Bottoms, Oily Wastewater, Used Oil, Contaminated Sand, Contaminated Catalyst, Drilling Fluids, Hydrocarbon Sludge and Petrochemical Sludge. It consists of two steps, First by mechanical separation and second by Thermal separation.

Three Phase Centrifugation System

A high rate three-phase centrifuge system is used for hydrocarbon recovery and recycling operations, Oily waste are separated into their component parts of oil, water and solids using a high speed centrifuge where the recovered oil can be reused.

The water discharged will average below 2000-PPM total suspended solids and less than 1-% free oil. The hydrocarbon stream will be equal to or less than 1% .BS&W, depending on the feed material.

The solids will be approximately 50% solids by weight and will discharge, via screw conveyor, into a roll-off box for disposal or further treatment by TDU to eliminate total hydrocarbon and oil to 1% TPH.

Thermal Desorption System

A high rate three-phase centrifuge system is used for hydrocarbon recovery and recycling operations, Oily waste are separated into their component parts of oil, water and solids using a high speed centrifuge where the recovered oil can be reused.

The water discharged will average below 2000-PPM total suspended solids and less than 1-% free oil. The hydrocarbon stream will be equal to or less than 1% .BS&W, depending on the feed material.

The solids will be approximately 50% solids by weight and will discharge, via screw conveyor, into a roll-off box for disposal or further treatment by TDU to eliminate total hydrocarbon and oil to 1% TPH.

- Operation optimized to 24 hrs

- Capacity: 6-8 m3/hr

- Easy mobilization

- Excellent 3 phases separation

- Substantial volume and waste reduction, generally greater than 80%

- Recover oil and water for reuse

- Substantially reduces disposal and incineration costs

- Detoxification of solids to inert materials for safe disposal

- Recovery of valuable hydrocarbons

- Flexible process capability for waste streams and throughput capacity.